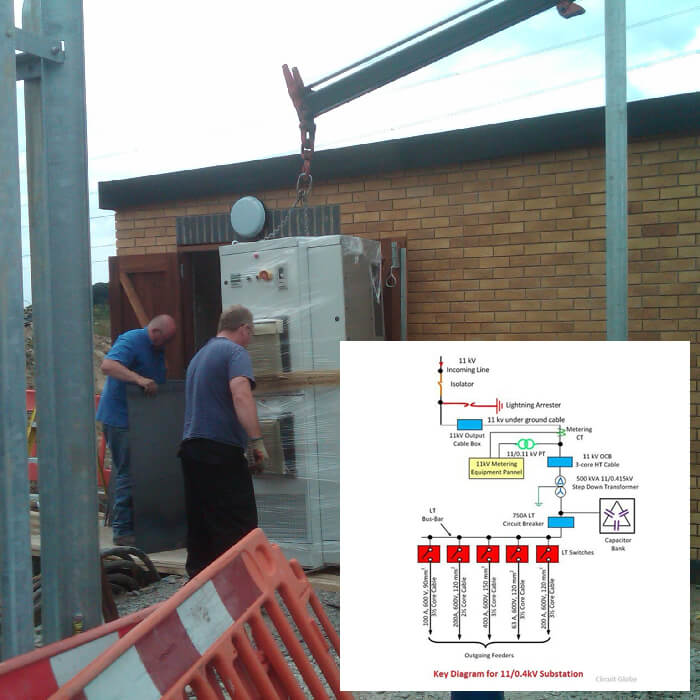

This New Build Factory required, an on-site electrical sub-station, Stand-by Emergency power for the refrigeration plant and a second generator to maintain production.

The Team completed, a BREEAM compliant building, to incorporate large motor electrical supply distribution boards arranged in a Grid pattern to provide flexibility, PIR controlled lighting, treated water for the Steam Plant.

We specified the Main electrical distribution panel, sub-main cables and all lighting and power equipment, liaising with specialist suppliers to ensure their power and water needs where met.

The Mechanical installation design included, Heating & Plumbing systems.